Descripción

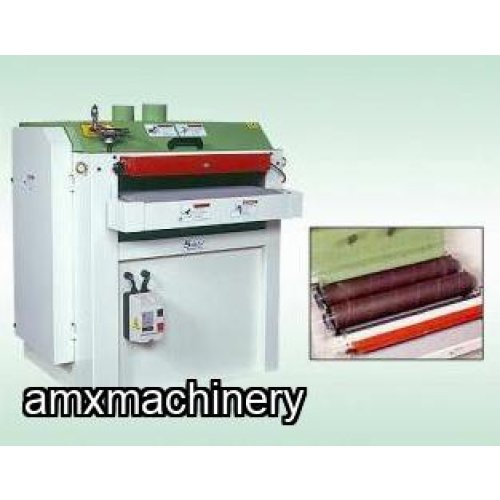

PARTE: 3UD-SUR1300V – LIJADORA CALIBRADORA SUPERIOR E INFERIOR – 1300 MM (51”) - ANCHO

NUEVA CON GARANTIA

Rack sheet metal part

1) The lower body is made of heavy-duty base, which is welded around

the whole with a whole plate, and the bottom is welded with dense channel

steel and steel plate connection, which enhances the stability and strength

of the lower body and ensures that the base is not deformed;

2) The conveying bed is welded with 18mm thick steel plate, and adopts

smoldering process to eliminate internal stress and ensure the accuracy

and sanding accuracy of the conveying bed;

3) The fixed-thick roller cantilever is made of large 180*200 rectangular

tube, with high strength and good stability;

4) The beam base and hanging plate are made of precision castings,

which can effectively absorb shock and ensure permanent deformation;

Sanding Roller Unit -1

1) The sanding machine adopts the combination of digging pressure plate

pressure roller.Press the plate to ensure that the plate is always in

contact with the loss during the sanding process.

Send tape tightly to fit.

2) The bottom sand machine uses the pressing plate and the pressing

roller to press the plate.

Ensure that the sheet always closely adheres to the conveyor belt during

the planing process.

3) The first group of sanding adopts ₵240mm large diameter eccentric

spiral steel fixed thickness roller to achieve the fixed thickness sanding

effect.

4) The second group of sanding adopts ₵240mm eccentric spiral rubber

fixed thickness roller to achieve fine sanding effect.

5) Safety protection is equipped with ultra-thick material detection device

and anti-reverse device, and is equipped with an inert pressure wheel

structure, which can effectively ensure the safety of the operator.

Sanding Roller Unit -2

The sand loading machine adopts the close-range

pressure roller structure

1) The first group of sanding adopts ₵270mm large diameter eccentric

spiral steel fixed thickness roller to achieve the fixed thickness sanding

effect;

2) The second group of sanding adopts ₵270mm eccentric spiral rubber

fixed thickness roller to achieve a fine sanding effect;

3) Safety protection Equipped with ultra-thick material detection device

and anti-reverse device, and equipped with an inert pressure wheel

structure, which can effectively ensure the safety of the operator.

Feeding Unit

1) The fixed-thickness roller adopts Japanese NSK bearings, which

extends the working life without maintenance and improves the reliability

of equipment operation.

2) The conveyor belt is made of WL12-GY special sanding machine belt,

the surface layer contains rubber, the surface has excellent wear

resistance and large friction, and is fed through the frequency conversion

helical-spiral bevel gear reducer, which is more smooth and powerful.

3) The lifting of the conveying platform adopts a worm gear worm lifting

motor and is equipped with a double chain drive, which has a compact

structure, high reliability and long service life.

SANDING ROLLER PART-2

1) Both sanders use Siemens controllers, intuitive operation and good

stability.

2) The light control adopts the German "Pepperl" brand photoelectric switch

with strong penetrating power, large effective distance and durability.

3) The limit switch adopts the Japanese "Omron" brand, which is flexible,

durable and has a long service life.

4) Both the internal circuit breaker and AC contactor of the distribution box

adopt German "Siemens" low-voltage electrical devices, which are safe,

reliable and have a long service life.

5) Proximity switch adopts high-quality parts from South Korea "Autonics",

which is sensitive and adjustable and reliable in use.

6) The start buttons are all Siemens illuminated buttons, intuitive and visual,

7) The motor is selected from the HM2 series three-phase asynchronous

motor produced by China's first-class enterprise "Shandong Huali Motor

Group Co., Ltd.", which has good stability, sufficient power, protection class

IP54, and durable.

8) The solenoid valve, throttle valve and air pressure contr

TECHNICAL DATA

ITEM SUPERIOR SANDER INFERIOR SANDER

Max.processing width 1300mm 1300mm

Min.processing length 490mm 490mm

Processing thickness 2-100mm 2-110mm

Feeding speed 5-36m/min 5-30m/min

Sanding belt size 1330×2200mm 1330×2200mm

First power 30KW 30KW

Second power 22kw 22kw

Feeding power 4kw(Frequency) 4kw(Frequency)

Up and down power 0.55kw 1.1kw

Vacuum power 5.5kw -

Air pressure 0.6Mpa 0.6Mpa

Air consumption 17m³/h 17m³/h

Dust collect capacity 8500m³/h 8500m³/h

Overall size 2164x2720x2256 2112×2634×2061mm

Weight 5600kg 4570kg

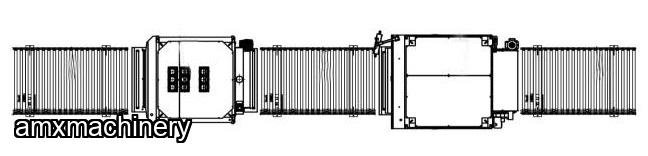

FEEDER ROLLER TABLE

Belt size 1300*2500*1100

Processing thickness 10-80mm

Max.feeding weight 600kg

Running speed 1-30m/min

Pago y Devoluciones

- Forma de pago

- Visa/Mastercard/American Express